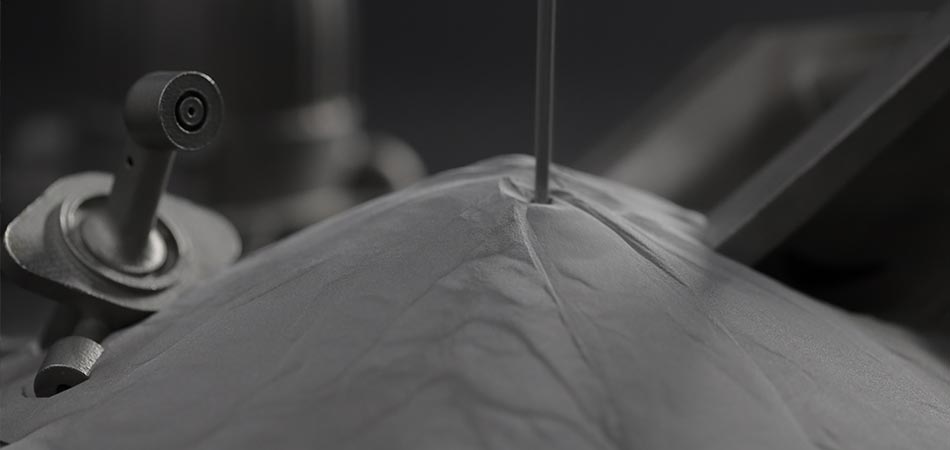

適制材料

Nickel-based Alloys, Cobalt-chromium Alloys, Stainless Steel, Aluminum-based Alloys, Iron-based Alloys, Etc.

2020 官網升級中!現在您訪問官網的瀏覽器設備分辨率寬度低于1280px請使用高分辨率寬度訪問。

VIGA equipment has a wide range of applications, mainly for the production of high-performance iron-based, nickel-based, cobalt-based, aluminium-based, copper-based and other advanced alloy powder materials. It is widely used in aerospace, health, tooling, automobile, machinery, electronics, new energy and other fields and also suitable for additive manufacturing (3D printing), melting deposition, laser cladding, thermal spraying, powder metallurgy, hot isostatic pressing and other advanced manufacturing processes.

Nickel-based Alloys, Cobalt-chromium Alloys, Stainless Steel, Aluminum-based Alloys, Iron-based Alloys, Etc.

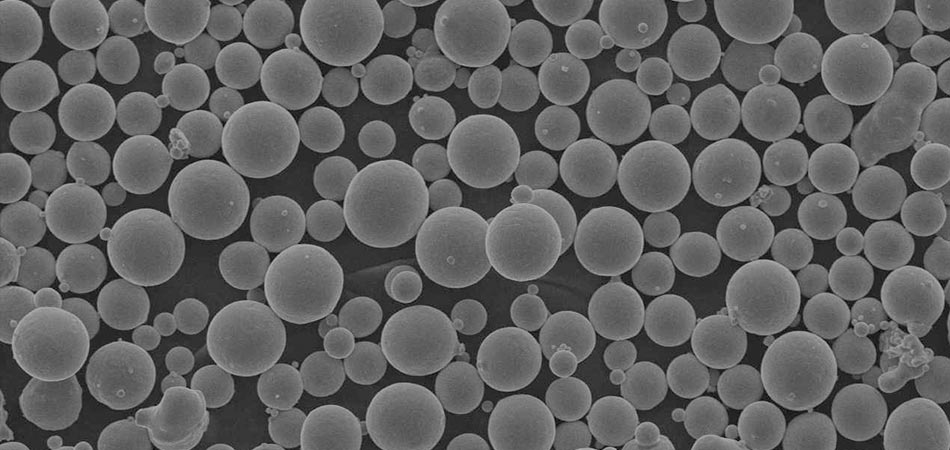

particle size 0~150μm, nickel-based alloy powder D50: 20~60μm

High powder yield, low oxygen content, good sphericity and excellent overall performance

Crucible Capacity

Pouring Method

Max Temperature

Temperature Measurement

Holding Temperature

Overall Power

Working Vacuum Degree

Ultimate Vacuum Degree

Pressure Rise Rate

Inert Gas

Atomizing Gas Pressure

Atomizing Gas Flow

Size Distibution

Build Size

10~500KG

Stopper Pouring for Small Furnace, Tundish Pouring for Large Furnace

≤1750℃

Mechanical and Dual Colorimetric Thermometry

1250℃

100~650KW

6.67×10-1Pa

6.67×10-3Pa

≤2Pa/h

N2 /Ar

0~6MPa,Nozzle: 8MPa

10~30Nm3/min

15~45μm, 15~53μm, 53~150μm

Depending on the type of furnace